What is an airsoft gearbox?

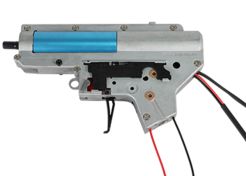

The airsoft gearbox is the metal housing that holds all moving parts of an AEG airsoft replica. Strictly, the airsoft gearbox is purely this housing, although many will say gears form parts of the airsoft gearbox too. In the upper part of the gearbox, all parts related to air are placed. The lower part holds all the electromechanical parts, like the gears and trigger.

Usually, an airsoft gearbox is a complete unit and if you want to change something inside, you’ll need to dismantle the whole replica. However, V2 gearboxes (we’ll mention the other versions in a bit) are also available as a split airsoft gearbox, where the upper part and lower parts can be separated from each other. Which means changing a spring is just a case of folding open the replica, to take out the upper part of the gearbox, while the lower part will stay put.

Best airsoft gearbox

Ah, there’s an impossible question if there ever was one. However, we can tell you a bit about the different versions and the airsoft gearbox upgrades you can do with the airsoft gearbox parts that we have available. There are loads of standard gearboxes, but many of them will fit just a specific model or some less popular models. The latter means that these are not very interesting for manufacturers of upgrade parts to design parts for, which means they don’t. So, for that reason, we’ll just mention the four most common airsoft gearboxes, coupled with the platforms and models that they’re intended for:

- V2 – M4. G3, MP5 (except the K), M16, AR15

- V3 – AK, G36, MP5K, AUG

- V6 – P90, Thompson

- V7 – M14, Sten

All that moves, will wear. And that means airsoft gearbox parts will need to be replaced every now and then. Of the four gearboxes mentioned above, the gears, cylinders, pistons and piston heads are interchangeable. What differs, are the cylinder heads and nozzles. Upgrade parts for them are plentiful, which means you won’t have any problems keeping them well maintained, nor will you have any problems finding airsoft gearbox upgrade parts. More about that in a minute. What we just like to point out, is that every standard gearbox can be upgraded with the right parts. Nylon gears can be changed for metal ones, et cetera. So you can make it the best one for your airsoft replica. However, there’s no use comparing airsoft gearboxes, as not all of them will fit the same replica’s.

Airsoft gearbox upgrade

We’ve mentioned airsoft gearbox upgrade parts. And their compatibility in the different gearboxes. These parts don’t only give you the opportunity to change worn parts for new, often better, components, they also provide you with the means to do some tuning. With tuning, you change characteristics, enhance reliability and durability, while also boosting performance.

Let’s have a look at the possibilities:

- Metal gears are a lot more durable than synthetic ones, while being able to cope with more forces. And when talking gears, know you can change the gear ratio too. Standard ratio is 18:1, which means the motor turns 18 times for one cycle. When you choose a low ratio like 13:1 (super high speed), you improve the rate of fire, but the motor could struggle. If you go the other way and opt for a high ratio like 32:1 (high torque), the motor will have to work less hard. Such a ratio is advisable when using a heavier spring. However, we don’t see many airsofters experimenting with the gear ratio. For speed or power, they just grab a suitable motor and be done with it.

- Double sector gears could be interesting for dramatically upping the RPF (rounds per second). When we say improving, we mean doubling it, as the double sector gear has two toothed sectors that pull the piston back. The concession that you’ll make, is also halving the stroke, as the piston is now only pulled back halfway. This means less power. Besides double sector gears, there are also triple sector gears.

- Bushings in which the gear axles turn, can be replaced by bearings. These will let the gears turn more smoothly, with less loss of friction, theoretically meaning more speed. Some decide to go the other way around and change bearings for bushes, as these are more silent.

- A split airsoft gearbox is a sound investment too (for V2 gearboxes), as the upper and lower part are split, which means they can be disassembled separately. This’ll save a tremendous amount of time when, for example, changing a spring. Where normally the complete replica needs to be dismantled, there’s no need for that with a split gearbox. After folding open the replica, the top of the gearbox can be taken off, while the lower part with all the gears neatly stays put.

- A cylinder can be changed for an airsoft upgrade part. Usually, the tolerances are smaller, making for a better fit and a more consistent air seal. Ergo, more pressure. And the materials are often more durable too. You can also play with the cylinder capacity, but please read into that before you do, as the ratio between cylinder capacity and the capacity of the barrel need to be well matched.

- Of course, the cylinder head can also be replaced with an upgrade part, made from better materials and with a better, airtight fit for more consistency.

- The piston is definitely worth mentioning too. Just like the cylinder parts above, durable materials and a perfect fit make for less wear and more consistency. And the teeth can be metal too, which goes a long way in durability compared to synthetic teeth.

- We’ve looked at all the internals of the airsoft gearbox, but the housing itself can be upgraded too. The main advantage here is that all the cut-outs are radiused, which means all windows in the housing have their corners rounded, to prevent stress cracks. These cracks quite often appear in standard housings. Sometimes just because of fatigue due to years of use, but often because of tuning creating more forces on the housing.

Many other upgrades are possible, all connected with the airsoft gearbox. For that, we recommend having a look at our Airsoft parts page.

Airsoft gearbox maintenance

Maintenance of an airsoft gearbox always begins with cleaning all the parts. To do that, the complete gearbox needs to be dismantled, even if it’s a split gearbox. Not until after all the old grease and dirt are removed, all parts can be inspected for wear or damage. This is how you do just that:

- Gears are checked for worn teeth (one side will have a different angle) or even broken teeth. While you’re at it, you might as well check the axles of the gears for play in the bushings or bearings by wobbling them.

- Pistons can be checked, just like gears for worn or broken teeth. Also, check the air seal by placing your finger against the port and press against the piston in the cylinder. There shouldn’t be much air escaping.

- Cylinder heads are easily checked by placing a finger in front of the nozzle and pushing the piston, just like you did with the piston check. As the piston now is in the equation, air leakage will be a bit more, but it shouldn’t be excessive.

- Springs are best checked by measuring the speed (fps). If you don’t have a chrono, you can write down the free spring length of a new spring before assembly (tip: write it on the cylinder with a sharpie). When worn, the spring-length will be notably shorter.

- Bushings are hard to visually check. The holes are too small to measure, but sometimes you can notice the hole being oval. Best is just to feel if there’s play on the axle.

- Bearings can be checked for feelable play, by sticking an axle in them. You can also try to feel if they turn smoothly. Worn or dried out bearings will feel a bit rough, like they’re somewhat bumpy inside.

After checking the parts and replacing the worn ones with airsoft gearbox upgrade parts, it’s time for lubrication and assembly. The gears are lubricated with grease, as this will stay put better on fast rotating parts, while also providing a thicker layer that will dry out less quick than oil. As the gears are hidden deep inside the gearbox, maintenance intervals are quite long, so make sure they are well-greased. After the gears, you should focus on the sliding parts, such as the tappet plate, for which both oil and grease can be used, or a gel that holds the middle between these two. Oil is then used on the O-rings of the piston and cylinder head, as well as for pivot points. Also oil the axles of the gears in their bushings (from the outside). And if you use open bearings, you can oil these too, although grease will be better if you manage to get it in these micro bearings.

Airsoft gearbox upgrades online

When shopping for an airsoft gearbox, it’s important to know which version you need. The different versions are mentioned above under the title ‘Best airsoft gearboxes’. You can buy a complete airsoft gearbox in our online shop, but it’s also possible to buy an empty airsoft gearbox housing and fill it with our airsoft gearbox upgrade parts, such as gears, cylinder, cylinder head, piston, bushes/bearings, et cetera. Please feel free to ask our experts for advice through e-mail, chat or phone.

Fast & secure delivery

Fast & secure delivery Secure shopping & payment

Secure shopping & payment Lots of expertise

Lots of expertise