-

Reloading presses & accessories

Case cleaning

Case processing

Powder processing

Powder measure & accessories (6)

Tools & other

A complete reloading shop inside Krale

We’re taking reloading and handloading very serious and have stocked a substantial part of our shop with reloading supplies and handloading supplies. You can almost say it’s a shop inside a store. From reloading presses to cases, all reloading supplies are on display and available (if shipping to your country is allowed) in our online reloading shop. And, of course, if you happen to have any questions about reloading or handloading, our experts will do their very best to inform you. They can explain how to operate the reloading equipment and know which components work well together.

The reloading supplies and reloading equipment that we have on offer is suitable for both sport shooting and hunting. So, if you’re reloading 9 mm ammo or if you’re handloading .308 Win cartridges, we’ve got all the equipment and reloading solutions for sale for professional and safe reloading and handloading.

Reloading vs handloading

You’ve noticed we’ve been using reloading and handloading to describe the process. They’re different terms for the same thing… but there is a difference. Reloading is often done for economic reasons by shooters that will spend a lot of cartridges, such as sport shooters. By collecting the empty cases and reloading them, a significant reducing in costs can be established. Looking at the different components of a cartridge, the brass case is the most expensive component, often accounting for more than half of the costs. Especially when looking at reloading as a hobby, it’s an interesting and cost-effective thing to consider.

Then there’s handloading. Handloading ammo is the definite way to ultimate accuracy and we’ve got all the high-end handloading supplies for you to create the very best cartridges. Cost saving isn’t priority when handloading, it’s sheer perfection that handloaders are after. They’ll choose and sift the best cases for weight and size, doing the same for primers and bullets of choice. The powder is carefully selected and weighed precisely up to the last grain. Cases are sized and trimmed. Anyway, you get the picture. The whole point of handloading is to take away the margins that manufacturers inevitably have to keep sale prices affordable. By doing that, you can make batches of handloaded ammo with unmatched uniformity, translating in unmatched consistency.

Reloading can also be a great solution when using classic guns with obsolete ammunition or guns with rare calibres that are difficult to obtain. There are plenty of reloading solutions to keep you shooting.

Reloading supplies and handloading supplies

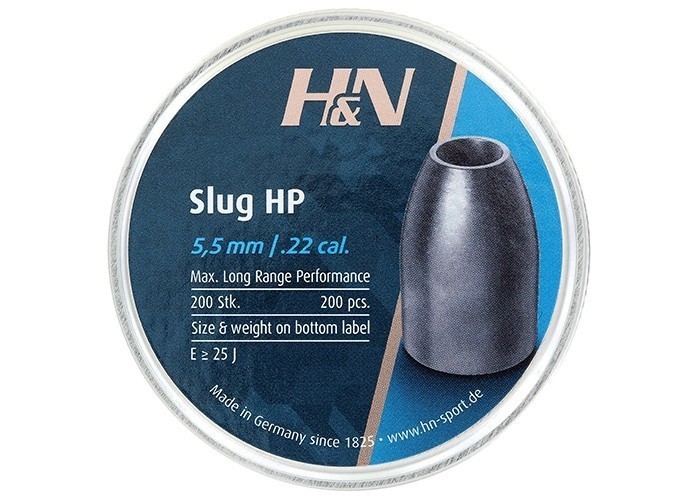

For reloading, four basic components are needed. The first will be the brass case. You can buy new cases in lots of calibres (for the handloader), but you can also recycle your old cases (reloading). A primer is pressed into the case, after which you’ll fill it with the right quality and perfect quantity of powder. Then, a bullet with the right calibre and shape is pressed into place, finishing your cartridge.

Reloading equipment

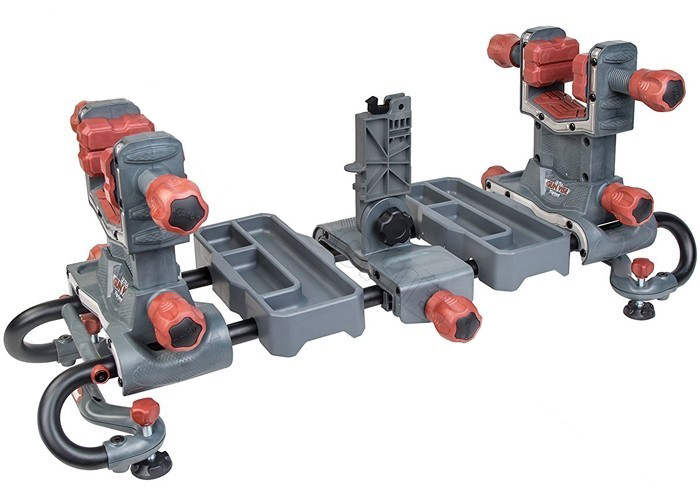

To be able to reload by yourself, you’ll be needing some reloading equipment. A reloading press will be the first thing to get, together with dies, shell holders, shell plates, et cetera. With these, cases are swaged into uniform sizes. But a reloading press is also used to remove and press in primers and to seat bullets. A case trimmer will cut every case to the perfect length. And the powder is weighed and dispensed with scales, powder dispensers, powder tricklers and powder funnels. Cases are cleaned in case tumblers with wet and dry media and polishing compounds or in an ultrasonic cleaner. You’ll dry them afterwards in a media separator.

The reloading process explained

Apart from sorting and weighing the separate components (like blueprinting), the process of reloading is similar to that of handloading. For this reason, we’ll explain to you how safe reloading is done.

- Logically, you start with pressing the spent cartridges out of the empty cases with your reloading press. The cases are now completely empty and ready for cleaning in a case tumbler with media and polishing compound. Wet or dry, you can choose that to your own preference. The third option is an ultrasonic cleaner. Powder residue and contamination are removed, and the cases come out as new. Put them in the media separator to dry them and remove any media.

- After checking the cases for damage (they do have a lifespan), you then grease them with case grease before swaging them perfectly to size in the different dies. It’s important to do this, especially with bottleneck cases, to prevent them getting stuck inside the dies. As the power of the explosion when the cartridge is shot, will slightly expand the case and the case opening, they have to be swaged (or crimped if you prefer) back to size. The case opening is quite critical, as the bullet needs to be clamped with the correct amount of friction for a perfect interference fit. While sizing, the cases are pushed back into shape, but as the material is stretched a bit, compressing them will result in making them a bit longer. By shortening them with a case trimmer, they can be returned to their original size. The edges are then deburred with deburring tools for a perfect finish.

- With the cases cleaned up and sized, it’s time to press the primers into place. Again by using a suitable die in the reloading press.

- After the prime is placed, it’s time to fill the case with the correct amount of powder by using a powder dispenser or powder measure. Another way is using a powder trickler, scale and powder funnel.

- To finish the cartridge, the bullet is pushed in place (seated) with a perfect and uniform interference fit.

The different steps can be done on a single stage reloading press, clamping down the case in a shell holder and changing dies. There are also multi-stage reloading presses, the so called progressive reloading presses, where the cases are clamped in a rotating shell plate, passing multiple dies in one go. With a reloading press, you can press out and press in primers, stretch and crimp the case opening, load powder into the cases and seat the bullets.

We also stock other reloading supplies like feeders, reloading trays and hand tools. And if you happen to make a mess of things, there’s always the trusty bullet puller to safely remove the bullet from a loaded cartridge. Safety is key when reloading and handloading.

Fast & secure delivery

Fast & secure delivery Secure shopping & payment

Secure shopping & payment Lots of expertise

Lots of expertise