What is a case tumbler used for?

A use case (shell) is contaminated with powder residue, carbon deposits and sometimes even oxidation. If you want to reload or handload these cases, they’ll need to be cleaned as contamination can prevent good seating of the primer or the bullet. And you want the inside of the cases filled with fresh powder, without it being contaminated by residue. But most importantly, you want the outside of the cases free from dirt and grime to prevent premature wear on your dies and other tools. Another advantage of cleaning your brass, is that it’s easier to spot damage that could let you decide not to use the case anymore as, every case has a lifespan.

So, what it all comes down to, is that for reloading, your cases should be perfectly clean. That way, they are identical again and being identical is the recipe for consistency. To get them that way before reloading, they need a thorough clean. Not just a rinse, but a deep clean. You can clean them by hand with a brush, abrasives and cleaning agents, but a case tumbler will do a far better job. And it’s quicker too! A brass ammo tumbler isn’t just a lazy option, it is the best option for a proper cleaning with a consistency that you could never get by manual cleaning.

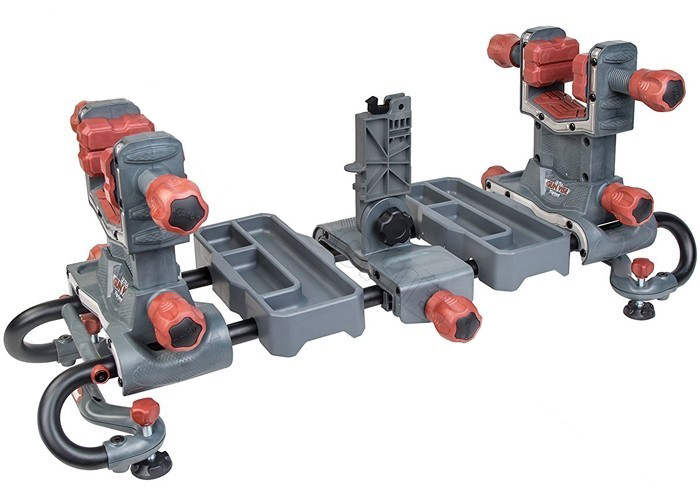

Rotary vs vibratory tumbler

Simply said, there are two ways to give your cases a good clean in a case tumbler: wet or dry, for which you need a vibratory or a rotary tumbler. Both methods have their pros and cons and which one will suit you best, is predominantly your own preference. We can give you some advice, after which you can decide for yourself which is the best brass tumbler for you.

Dry tumbling is done with a vibratory reloading tumbler. It’s filled with media such as corn hob (dried and ground heart of a corn hob) or walnut (ground walnut shell). Walnut is harder and will clean a bit more aggressively and thoroughly, but doesn’t polish that much. A polishing compound can be added to both media (some even have it integrated in the formula), but when polishing is important for you, corn hob will do the best job. Which one is better? Well, forums are full of discussions and friendships have suffered trying to answer that… The advantage of dry tumbling is that it’s quick. The disadvantage is that it’s quite noisy.

After tumbling, you have to sift the cases from the media. A sieve can be used and another option is a rotary media separator that you slowly alternatingly rotate by hand. The media can be poured back into the brass tumbler, ready for another use as media can be used multiple times. Your cases will be bright and clean on the outside, but the inside can still have some residue left. That’s because the relatively light media has too little space inside the case to perform a proper abrasive rubbing action. Many reloaders won’t mind, they just want the outside of the brass clean to prolong the lifespan of their tools and to make the reloading process a bit cleaner.

However, if you want the inside of your cases also clean as a whistle (for ultimate uniformity in cases, translating in more consistency of the cartridges), we recommend wet tumbling in a rotary tumbler. In a rotary tumbler you put water with a cleaning agent, a polishing compound and stainless media. Stainless media consists of tiny stainless bars, made from magnetic 304 stainless steel. They’re very abrasive and will do a good job, even inside the cases. And stainless-steel media is re-usable indefinitely.

After the cleaning cycle inside the rotary tumbler, the cases aren’t ready for use just yet, like they would be with a vibratory tumbler after sifting. You need to sift the stainless media too, of course, using a slow spinning media separator or a magnet. But after this, you also need to dry the brass. You can let the cases dry naturally, but we’ve also got a brass dryer. Inside that case dryer, hot air is blown through multiple grilles on which the cases are laid out.

Looking at the total process, a wet tumbling rotary brass tumbler is slower than the dry tumbling vibratory tumbler, as the process has the additional step of drying. But while it may take longer, your cases will be like new inside and out. There will be no contamination anywhere. And if you took the primers out in advance, even the primer pockets will be perfectly clean. And you won’t need to pick media out of those primer pockets, like you sometimes will with dry tumbling media. One last point to mention is that, while the process may be a bit slower, it’s more silent too.

Buying the best brass tumbler

With all the information above, you should be able to make a well-considered decision between a vibratory tumbler or a rotary tumbler. Yet, there’s still one thing to consider, and that’s how large your brass ammo tumbler needs to be. Of course, this will depend on the calibre you’re using, but also on the amount of brass you want to clean. A large case tumbler will carry a lot of cases, but will need more media and will take up a bit more space too. So, if you’re not spending a lot of cases and/or use a small calibre, often a smaller case tumbler will do just fine.

Come and have a look at the case tumblers in our shop if you are in the Netherlands and don’t hesitate to ask our experts for advice. Equally, feel free to ask our customer service for help if you need it, and order a brass tumbler in our online shop. It’ll be sent to you fast and well-packed.